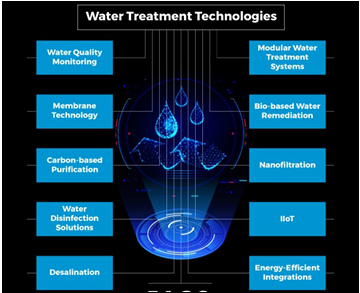

Contamination remains one of the most pressing issues in water treatment. Pollutants such as heavy metals, pesticides, pharmaceuticals, and microplastics pose significant health risks. Furthermore, pathogens, including bacteria and viruses can enter water sources and lead to outbreaks of waterborne diseases. Population growth and industrialization further stress water resources, highlighting the need for innovative solutions to meet rising demand. The water treatment industry has embraced several transformative technologies to combat contamination effectively and enhance treatment efficiency. These include AI-driven monitoring, advanced filtration systems, smart infrastructure, membrane filtration, bio & carbon-based purification, modular systems, desalination and more.

Out of many trending technologies, Modularisation of treatment facilities is one of the fastest growing trends. This article explores the key benefits that make modular water and wastewater treatment plants an attractive option for modern infrastructure projects.

Modular Water Treatment Plants

They are pre-engineered systems designed to treat water efficiently while being adaptable to different scales and requirements. Water treatment plants often require extensive infrastructure and are not easily adaptable. On the other hand, modular water treatment systems offer a portable, scalable, and customizable solution using prefabricated units that are easy to transport, assemble, and integrate. These technologies are designed to adapt to various site conditions and project requirements, making them a versatile and cost-effective option for water and wastewater treatment applications. These systems can be deployed quickly and are ideal for both urban and rural settings. They are particularly beneficial in situations where traditional large-scale plants may be impractical or too costly.

Recent advances in modular technology include the integration of processes such as membrane filtration, advanced oxidation, and biological treatment to effectively remove contaminants and improve water quality. The modular approach also allows for efficient monitoring, control, and maintenance of water treatment systems.

Water Treatment Methods Deployed in Modular Solutions

A modular plant is not just a containerized system — it’s a fully functional treatment facility built with precision and adaptability. The preliminary treatment stage serves as the first line of defence in water management, designed to remove coarse and settleable solids that could otherwise damage downstream process equipment or hinder biological activity. Mechanical screening units are employed to intercept large floating and suspended matter such as plastics, rags, and debris. Following screening, grit chambers facilitate the sedimentation of heavier inorganic particles like sand, gravel, and stones under controlled flow velocities. The removal of these materials is critical to prevent abrasion, clogging, and excessive wear of pumps, valves, and subsequent treatment units.

The biological treatment phase, which is followed by primary treatment, is responsible for the degradation and stabilisation of dissolved and colloidal organic pollutants through microbial action. Common process configurations include the Moving Bed Biofilm Reactor (MBBR), Sequencing Batch Reactor (SBR), and Membrane Bioreactor (MBR). The MBBR utilises biofilm carriers to increase surface area for microbial growth, enhancing organic and nutrient removal efficiency. The SBR operates in time sequenced cycles of aeration and settling, enabling simultaneous carbon oxidation and nitrification – denitrification within a single reactor. The MBR integrates biological treatment with membrane filtration, offering superior solids separation and producing high-quality effluent suitable for reuse applications. These modular and compact configurations provide high treatment efficiency, process flexibility, and reduced footprint, making them ideal for decentralised or space-constrained installations.

The tertiary treatment and polishing stage further refines the effluent quality to meet stringent discharge or reuse standards. This stage typically incorporates sand filtration, activated carbon adsorption, and disinfection units such as ultraviolet (UV) irradiation or chlorination. Sand filters remove residual suspended solids and turbidity, while activated carbon filters adsorb trace organics, colour, and odorous compounds. The final disinfection step ensures microbial safety, rendering the treated effluents suitable for applications including landscape irrigation, industrial cooling, boiler feed, or other non-potable reuse purposes.

Advantages offered by Modular Systems

Traditional water treatment plants are often seen as time consuming, capital-heavy, and land-intensive projects. In contrast, modular solutions address these challenges directly. The forthcoming paragraphs throw light on various benefits offered by these systems.

While the operational cost of modular plants may be comparable or slightly higher than traditional plants, the overall project economics often favour modular solutions. The cost benefits fall into following categories:

● Minimal material waste: Factory production allows for precise material usage and recycling of off cuts, reducing overall material costs.

● Less labour costs: With most of the construction occurring in a factory setting, on-site labour requirements are significantly reduced. This not only helps in lowering the cost but also minimises accident risks.

● Reduced project cost: Reduced timelines for project implementation leads to lower project management costs. Shorter construction periods can also result in lower interest cost during construction for financed projects.

● Lower Maintenance: Standardised designs often lead to more efficient operations and lower maintenance costs over the plant’s lifecycle. A comprehensive cost analysis typically reveals that modular plants can offer savings of approx. 25 % over the total project lifecycle, when compared with traditional plants.

No Cost Overruns

Modular construction significantly mitigates many of the risks associated with traditional construction. Conventional water treatment projects often face delay due to weather conditions impacting cost. Modular plants, being constructed in factory, are unaffected by uncertainty of weather. Labour costs for factory built plants are predictable. Site specific issues are less encountered in case of modular plants, hence unforeseen costs due to ground conditions are reduced. Inventory of components helps meet timeline for factory construction of plants, which reduces risk of delays due to supply chain disruptions. Studies have shown that modular construction can reduce the risk of cost overruns by up to 50% compared to traditional methods.

Rapid Deployment and Installation

Traditional plants often require extensive on-site construction, which can stretch over several years, causing prolonged disruption to local communities. Modular units are largely prefabricated in controlled factory settings.

The off-site construction allows for independent and parallel processes like site preparation, module manufacturing, etc., which significantly reduces overall timelines.

Whereas a conventional plant may take 2-3 years’ period to complete, a modular plant of identical capacity can go into operation within 6-12 months from project initiation.

The speed of implementation not only addresses immediate needs but also allows for quicker return on investment. The speed of implementation is particularly crucial in scenarios such as:

● Emergency response to natural disasters

● Rapid population growth in urban areas

● Urgent upgrades required to meet new environmental regulations

● Temporary requirements for large-scale events or industrial projects

Consistency in Quality

In addition to speed of deployment and cost benefits, modular plants also deliver exceptional quality. Their factory-based production ensures a controlled environment, standardised processes, rigorous quality control, and a skilled workforce. While controlled climate of factories eliminate weather-related quality issues, repeatable manufacturing processes of factories ensure consistency across modules.

In contrast to on-site construction of traditional plants, modular plants inherit specialised skills of factory workers for particular aspects of modular construction. Moreover, plant construction within factory settings allow thorough testing and quality assurance before units leave the facility. Because of consistency in quality, the performance of plants is more reliable, having reduced variability in treatment efficacy, and lower failure rates.

Scalability and Flexibility

The scalability of modular water and wastewater treatment plants provides unparalleled flexibility in infrastructure planning and investment. Industries and municipalities can start with a base capacity and add modules as demand grows, aligning capital expenditure with actual needs. For urban areas, where population growth is uncertain, modular plants can be easily expanded or, if necessary, partially decommissioned to match population trends. Modular plants can easily absorb technological upgrades. As treatment technologies advance, individual modules can be replaced or upgraded without disrupting the entire system.

In case of changed regulations calling for additional treatment processes, relevant modules can be seamlessly added without overhauling the existing plant. This flexibility is particularly valuable in fast-growing urban areas, seasonal tourist destinations, or industrial zones with fluctuating demand.

Compact and Space Efficient

Modular plants occupy less space compared to conventional water treatment plants. Therefore, suitable for urban areas, industrial sites, and institutions where land is scarce.

Reduced Environmental Impact

With most construction occurring off-site, there is significantly less noise, dust, and traffic disruption in the local area. Factory production often allows for more efficient use of materials and energy compared to on-site construction, ultimately bringing the advantage of reduced carbon footprint. As modular plants typically cover lesser land area, more area of natural habitat can be preserved. Recycling and repurposing of materials is possible, which reduces waste disposal. The advanced control systems of modular designs help in optimisation of quantities of treatment chemicals, thereby brings a possibility of lower chemical consumption. Thus, modular plants are environmentally sustainable and promote green practices.

Portability

In scenarios where temporary treatment solutions are needed, such as in mining operations or disaster relief efforts, modular water and wastewater treatment plants offer the advantage of portability. They can be easily transported, relocated and reassembled as needs change, providing a level of versatility impossible with traditional plants.

Standardisation and Predictability

By virtue of standardised nature of modular plants, numerous operational benefits are derived:

● Simplified training: Operators can be trained on standardised systems, improving efficiency and reducing the likelihood of human error.

● Consistent performance and bench marking: Standardised modules behave predictably, allowing for more accurate planning and management of treatment processes. Standardisation allows for meaningful comparison of performance across different installations, facilitating continuous improvement.

● Easy troubleshooting and maintenance: As the issues are common in nature, they are more readily identified and resolved. Since components deployed are standardised, scheduling of maintenance tasks can be predictably done. These plants also bring advantage of simplified inventory management for spare parts.

Easier Financing

The financial sector is increasingly recognising the advantages of modular plants due to following merits:

● Cost estimation: The factory-based approach provides more accurate cost estimations, reducing uncertainty for financiers.

● Staggered investment: The ability to scale plants over time allows for staggered financing, reducing initial capital requirements.

● Shorter payback periods: Faster implementation of plant renders quicker revenue generation, improving project economics.

● Mitigated risk: Lower chances of delays and cost overruns make these projects more attractive to risk-averse investors.

These factors can make it easier for communities, municipalities and businesses to secure funding for water and wastewater treatment projects.

Integration of Innovation

Modular designs create a fertile ground for innovation in water treatment. New technologies can be tested in individual modules before being rolled out at full scale, enabling rapid prototyping and adoption. It becomes easy to incorporate new and emerging technologies into existing plants by replacing or adding modules, without disrupting the entire system.

The site-specific innovations made to address unique water quality challenges can be easily integrated into modular designs. It is also easier to integrate and upgrade advanced control and smart monitoring systems in modular designs. These plants also facilitate the adoption of innovations like advanced materials or IoT technologies from other industries. This flexibility in incorporating cross-industry innovations ensures that modular plants remain future-ready and continuously improving throughout their operational life.

CONCLUSION

Modular water and wastewater treatment plants are revolutionising the industry, offering a more efficient and sustainable alternative to traditional infrastructure. This innovative approach is rapidly gaining traction, addressing modern challenges and delivering numerous benefits across various sectors. They represent a forward-thinking solution to today’s water quality challenges. Their flexibility, rapid deployment, and cost-effectiveness make them an ideal choice for municipalities, industries, and remote communities that require a reliable supply of clean water.

A growing number of companies are responding to this demand.

Modular Water Treatment Solutions provide adaptable purification systems for a wide range of applications, including agriculture, marine operations, boiler feedwater, swimming pools, demineralisation, mining, humanitarian aid, the beverage industry, pharmaceutical uses, and drinking water treatment. As global water needs continue to evolve, modular solutions are set to play an increasingly important role in sustainable water management.

Whilst traditional water and wastewater treatment plants still serve a purpose — particularly for large-scale, complex projects — the advantages of modular systems are becoming ever more apparent. Therefore, they offer a compelling alternative that meets many of the challenges faced for modern water infrastructure development. Reflecting this growing interest, the global modular water and wastewater treatment system market is projected to achieve a CAGR of 8.7% by year 2030. This strong growth highlights the industry’s shift towards more adaptable and sustainable technologies. As we move toward a future where water scarcity and quality issues are becoming increasingly urgent, the adaptability and efficiency of modular treatment plants position them as a key solution for ensuring sustainable water management in communities around the world.